Dive Brief:

- Casella Waste Systems has partnered with BD, a manufacturer of syringes and other medical products, on a recycling pilot that it says has diverted 40,000 pounds of medical waste from disposal.

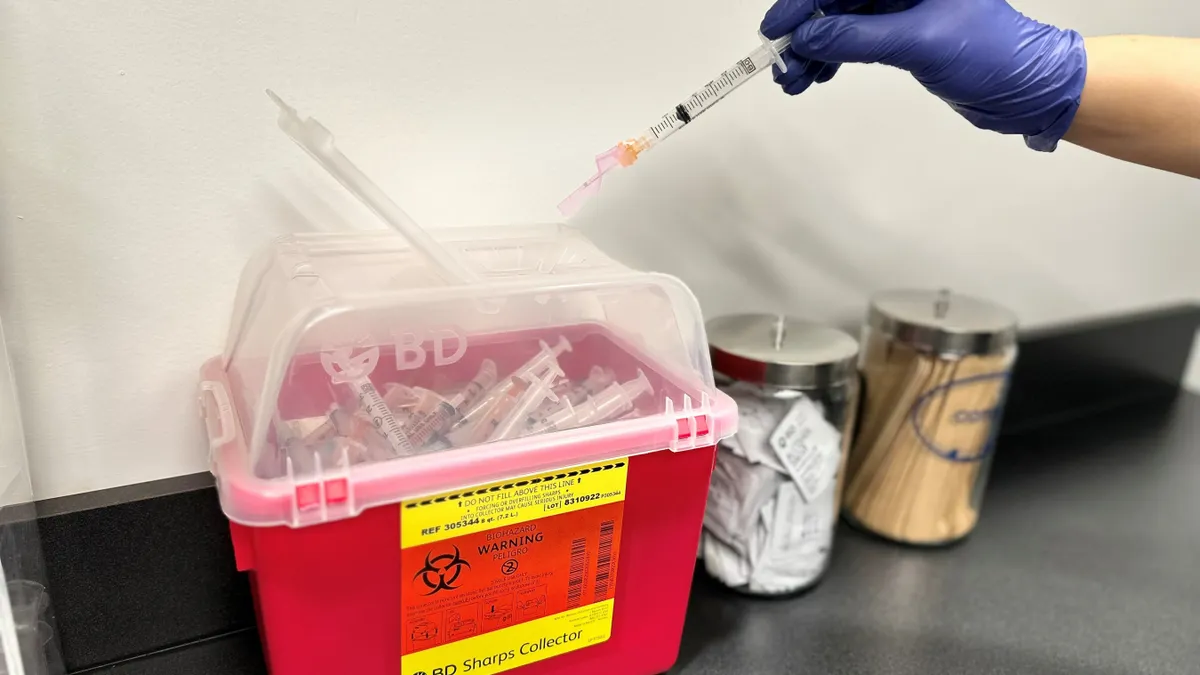

- Casella and BD collected discarded syringes from health care facilities and recycled the plastic components. The pilot also assessed the “technical feasibility” of using both mechanical and chemical recycling to process the material, which the companies said “showed favorable results.”

- The companies are now moving on to the next stage of the pilot, which will add more health care facilities to the program and identify other types of medical materials for recycling, as well as assess plans for reclaiming some kinds of used medical devices.

Dive Insight:

Casella and BD have worked together since 2013 to recycle materials from BD’s facilities, such as off-specification syringes and other manufacturing waste. This pilot, which took place in the first half of the year, is the first time the companies are branching out to collect and process medical waste at other health care facilities.

The companies didn’t disclose how many facilities participated in the pilot, but BD said syringe recycling is a hurdle across the health care field. Syringes are “particularly difficult to recycle due to the various components and steps involved in the process,” including safely handling the materials and putting the syringes through a sterilization process before they can be recycled, the company said in a news release. BD estimates syringes contribute to 3 billion pounds of plastic waste in the U.S. each year.

BD said the pilot showed that syringes can be disposed of safely while also lessening their environmental impact. Diverting plastic and other material from the waste stream, as well as achieving an 80% recycling rate by 2030, is part of the company’s ESG goals.

Casella works with BD at more than 30 of its locations. All of the plastic material collected during the pilot, including the containers used to collect syringes, was recycled, according to the companies. Once collected, Casella said it works with a network of recyclers and “medical waste partners” on managing BD and other facilities’ plastic scrap.

Casella’s role in the recycling pilot program is “a natural fit” because of the company’s previous experience with managing non-hazardous medical waste, including plastic, glass and metals from BD’s product lines, said Jeff Weld, Casella’s director of communications. Casella also provides BD with employee training and collects statistics on its recycling program, he said.

Casella sees the partnership as part of a long-term plan to recycle more medical waste in the future “and spur deeper thinking and advance processes that allow us to recycle more,” he said.